Sequence Programming - Complex components simply coated

Sequential programming allows serial coating of complex components

The central control unit MagicControl 4.0 with the option sequence program enables individual movement sequences of individual axes or entire stations. The sequence movements of X/Y-, synchronous, infeed or rotation axes for the coating of complex components can be programmed and managed effortlessly directly on the screen.

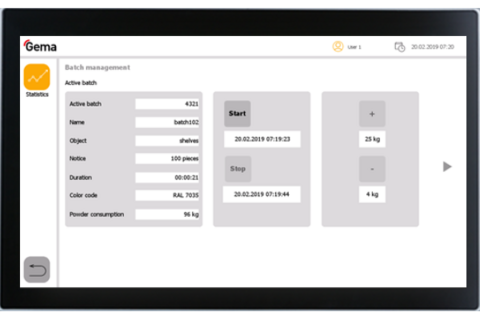

Batch Management - The powder consumption always under control

Partially automated powder quantity recording

The Batch Management System of the central control unit MagicControl 4.0 offers a tracking of the consumed powder, divided into production batches. The additional options “scale” and portable “barcode reader” extend the batch management and enable a semi-automated powder quantity recording.

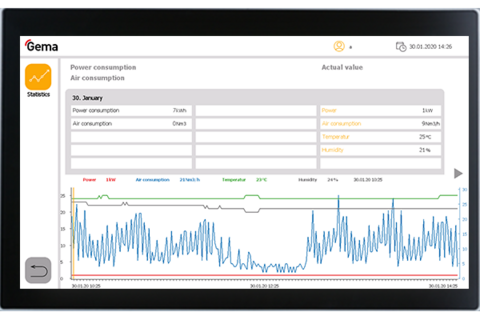

Energy Management - Manage and save energy easily

Energy and environmental data at a glance

The MagicControl 4.0 central control unit, with its two options for energy and compressed air consumption, forms the basis for energy management in order to monitor energy consumption, make optimizations in day-to-day operation and find ways of saving energy. As a further option, the thermohygrometer measures temperature and humidity during production.

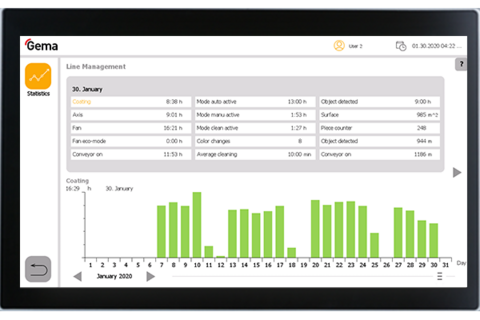

Line Management - Perfect partner for production

Operating data at a glance

The Line Management option visualizes the coating system on the screen of the MagicControl 4.0 central control unit. This gives the user a deeper insight into the utilization and efficiency of the line and enables to recognize potential for improvement of the production logistics.